The biggest concern during the design phase was to reach the automatic water change system via the ring main. As already reported, the supply line fulfilled the requirements perfectly, i.e. there was more than enough water in all the pools and it could also be regulated perfectly. Goal achieved.

But wait, where water flows in, it must also flow out again, and in a conceptual flow system, in the same quantity. When I tested the system, I only ran the water for 5 minutes at a time, everything was fine and I was happy because I could now change the water in all the pools at the same time and in less than 30 minutes. I only needed to operate one switch. But here, too, I had done the maths without the landlord.

If I let the whole thing run for longer than 5 minutes in real operation, the inlet still worked fine, but not the outlet. This was because, after the reservoir it contained had been filled within the first 5 minutes, it was completely overloaded, i.e. the system could not swallow the 50 litres/minute (1500 litres in 30 minutes) that continued to arrive……, and simply overflowed, the first major ‘I completely flooded the room’ event was complete.

Shoot, I hadn’t thought the system through to the last detail and installed a bottleneck. The solution to this problem was a smaller pump, which now only pumps an average of 25 litres per minute into the tanks (a little more at first, but then less and less as the water level in the tank drops over time). So now I need 50 minutes instead of 30, but I still only have to operate one switch, so let’s say I’ve (almost) achieved my goal.

Produce water change

Rainwater (2,500 litres total capacity) and the osmosis system manage to produce the required 1,500 litres within 15-20 hours without any problems. But what I hadn’t realised was that the water, whether from the rainwater barrel or from the well using reverse osmosis, is of course cold. That’s not really surprising. But what was surprising after careful calculation, or let’s be honest, what I had simply forgotten to calculate, was how much heat energy is needed to heat the water. And that adds up to a considerable amount of heat, namely around 800 kWh per year, which I had completely forgotten to include in the calculation of the heat balance for the room. It’s a good thing that the gas stove isn’t quite at the limit yet (so far) and, of course, the dehumidifier, which, as described above, brings a maximum of 1,500 kWh of extra heat into the room each year. So one thing fits into another quite sensibly, even if it wasn’t actually planned that way.

Energy balance rollover

And what about the goal of significantly reducing electricity consumption?

If we take out the parts that could not change because before and after (especially the side channel compressor and the UPS, together about 2,700 kWh per year), then the consumption for the rest of the room has halved from about 4,000 kWh to about 2,000 kWh (roughly € 500 less per year). If you now assume (which I don’t yet know for sure) that gas consumption will also fall significantly (I estimate that it will also be halved, i.e. another €280 less), then you’re already looking at a tidy sum of less running costs per year. But it is also clear that this alone is not enough to offset everything in 10 years with today’s energy costs. But it’s not just the energy balance, it’s also a lot less weekly labour time (water changes) and a significant increase in comfort in every nook and cranny. So the clear conclusion is that it was worth it. And I think everyone who has been able to visit the room will confirm this!

Water change, temperature and humidity during operation

I have already reported on the difficulties, but how does the interaction of all the factors work in practice? I will now try to bring everything together. In the meantime, I have tried out various strategies, i.e. weekly water changes of 30% in all tanks in one go, or sometimes only 10% several times a week, or even 60%. I now have a variety of options which – and this is the wonderful thing – don’t cost me any extra time (10% means just under 20 minutes, which can be left to run during the evening check and feeding).

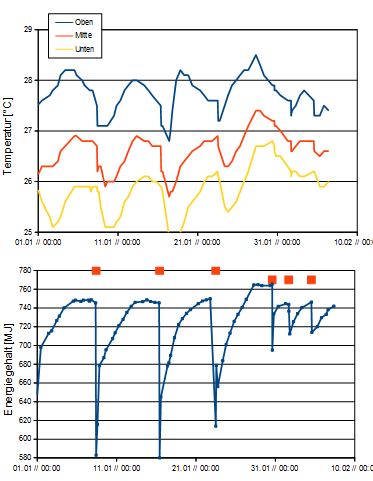

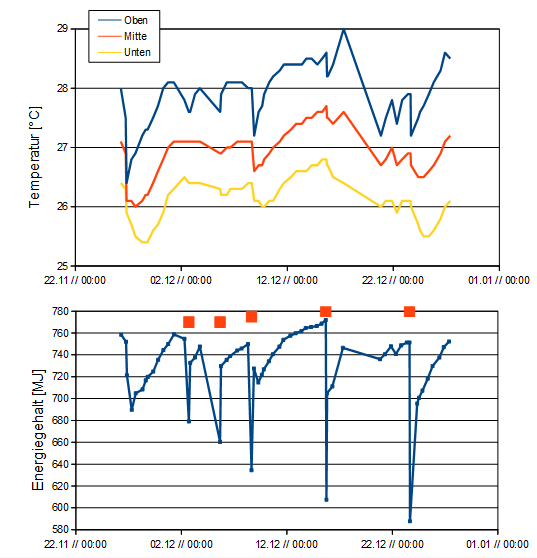

As mentioned above, I have now regularly measured the temperatures in the 3 rows for a few weeks, as well as those in the tank with the changing water (bottom and top). From this, you can calculate a kind of heat balance, which for the sake of simplicity only includes the energy quantities of the water in all tanks and in the tank. This can be used to create a great graphic that explains quite well what is happening:

In the lower part of the graph you can see when the WW (orange square) was made. The first two are WW of about 10%, the third of about 20% and the last two of about 30% each. You can clearly see that a huge amount of energy is dissipated from the room: with a 30% WW, around 150 mega joules leave the room in one go. That’s why Sandor’s advice on how to utilise this amount of heat sensibly was absolutely justified. When the tank is topped up, a lot of it comes back again and in the hours and days that follow, you then asymptotically approach the maximum amount again, so the heating has to work, otherwise it would be practically unemployed at these winter temperatures.

You can then see the result in the tanks (the graphic above). As already described above, in the bottom row there is only a slight cooling with a time delay, because the change water in the tank below has approximately the same temperature as in the basin, and the observed cooling then only occurs slowly due to the falling temperatures in the lower room area, determined by the very cold tank after filling. The situation is different in the upper row. Here the temperature drops directly with the water and then immediately begins to rise again gradually (but unaffected by the tank). Of course, the outside temperatures also play a role here, as does the aeration of the tanks (e.g. the intake filter of the side channel compressor was clogged during the first 30% WW, less air reached the air lifters, i.e. less evaporative cooling, etc.) and other factors. Incidentally, the humidity in the room rises slightly to just over 65% when the tank is filled (condensation on the outside) and then drops continuously to <60% until the next water change.

However, one problem remains: I had set the amount of incoming water for each tank in a rather lengthy procedure. It is clear that water is always changed in all tanks, even if there are no fish in them (you should always have free tank capacity because of quarantine, diseases, young fish, etc.). In addition, various changes were made after the primary setup, e.g. because a tank had to be temporarily removed due to changes in the installation or something. And now you have a problem because you can’t see exactly how much water is being exchanged in the individual tanks, precisely because the flow-through principle is used. Last week, I developed a system for measuring this so that I can subsequently adjust incorrect exchange rates to the intended rate of 30%: Measure conductivity, before and after as well as of the exchanged water. The amount of water exchanged in the tanks can then be calculated and the amount of incoming water corrected. And, as the first measurement showed, this is absolutely necessary, as some tanks were getting far too little and others far too much.